Designing 2K Molds: Index Plate, Rotary Platen, and Core Back Methods Explained

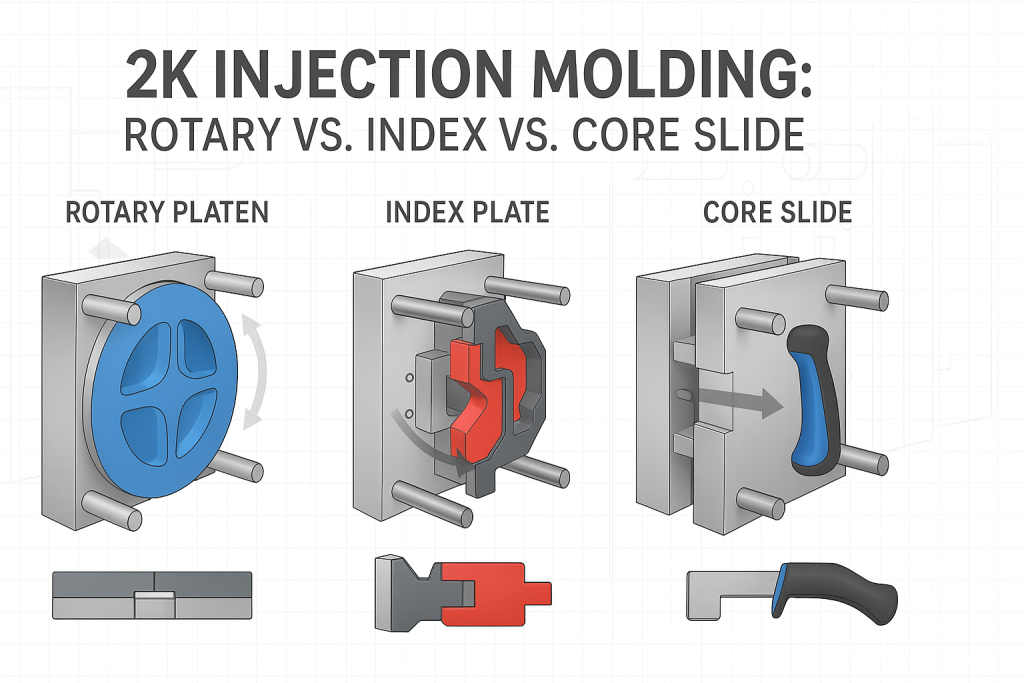

Designing a successful 2K mold requires choosing the right method to move the first-shot part to the second-shot cavity. The primary options for this transfer are the rotary platen, the index plate, and core slide mechanisms. Each approach has unique strengths and is suited for different types of parts and production volumes. As a leading manufacturer of high-precision 2K molds, we have engineered tools using each of these advanced techniques. The best choice always depends on part geometry, production requirements, and machine capabilities.

This guide will explain how each of these core 2K mold technologies works. We will break down the mechanics of rotary platens, index plates, and sliding cores. Understanding these methods is essential for any engineer or designer looking to leverage the power of two-shot molding. Making an informed decision at the design stage is the most critical step toward a successful, efficient, and cost-effective manufacturing process.

What is the Core Challenge in 2K Mold Design?

The fundamental goal of 2K Injection Molding is to create a single, integrated component from two different materials within a single machine cycle. The main engineering challenge is transferring the first molded part—the substrate—from the first cavity to the second cavity. This transfer must happen quickly, precisely, and reliably, thousands of times over. The substrate must be held securely while the second material is injected over, into, or around it.

This automated, in-mold transfer is what separates true 2K molding from a simpler process like overmolding. In basic overmolding, parts from one mold are often manually placed into a second mold for the next shot. This is a slower, more labor-intensive process. The advanced rotational and sliding mechanisms in 2K molds eliminate this manual step. This integration results in faster cycle times, lower labor costs, and improved part consistency. The method chosen to perform this transfer defines the entire design of the mold and the machine it runs on.

The Rotary Platen Method: Power and Precision

The rotary platen method is one of the most common solutions for high-volume 2K production. It is a robust and powerful system that relies on a specialized injection molding machine. This approach integrates the rotational mechanism directly into the machine itself, leading to a highly stable and efficient process.

How Does a Rotary Platen Work?

In this method, the mold has two core halves (the moving side) and two cavity halves (the stationary side). After the first material is injected to create the substrate, the mold opens. The entire moving platen of the press then rotates 180 degrees. This action physically moves the first-shot part from its position opposite the first cavity to a new position opposite the second cavity.

Once the rotation is complete, the mold closes again. As the first-shot station is being filled with new material, the second material is simultaneously injected over the substrate that was just moved into position. This parallel process makes the cycle very efficient. The finished two-material part is then ejected, and the process repeats.

When Should You Choose a Rotary Platen?

The rotary platen method is the ideal choice for several specific scenarios. It excels in high-volume production where speed and repeatability are the top priorities. The cycle times are typically the fastest among all 2K methods because the rotation is a single, swift machine action. This method is also well-suited for larger parts, as the machine platen provides a very stable and rigid platform for rotation.

However, this power comes with a significant requirement. It necessitates a dedicated 2K injection molding machine equipped with a rotating platen. These machines are a considerable capital investment. Therefore, this method is best reserved for long-term, high-volume projects where the efficiency gains justify the initial equipment cost.

The Index Plate Method: Versatility and Adaptability

The index plate method offers more flexibility than the rotary platen. Instead of rotating the entire machine platen, this technique uses a rotating plate inside the mold itself. This clever design allows for more complex part handling and can sometimes be adapted to standard injection molding machines.

Understanding the Index Plate Mechanism

An index plate mold also has two core halves and two cavity halves. The two core halves are mounted on a central plate that is engineered to rotate 180 degrees. After the first shot is injected, the mold opens. A drive mechanism—often a servo motor, hydraulic cylinder, or a rack-and-pinion system—rotates the index plate. This moves the core carrying the substrate over to the second cavity station.

The mold then closes, and the second material is injected while the first station is refilled. The key difference is that the rotation happens entirely within the confines of the mold. The machine's platen simply opens and closes. This internal movement makes the index plate a highly versatile solution for parts with complex geometries or asymmetrical shapes.

Advantages of Using an Index Plate

The primary advantage of the index plate is its design flexibility. Since it is not dependent on a rotating machine platen, it can be engineered for more complex movements. For instance, an index plate could be designed to include cooling stations or other intermediate steps. It is also an excellent choice for parts that are not balanced, as the rotation is contained within the mold structure.

While the mold itself is more complex and expensive to build than a standard mold, it can sometimes be a more cost-effective overall solution. In some cases, a mold with an integrated index plate can be fitted onto a conventional machine, avoiding the high cost of a dedicated 2K press. The trade-off is often a slightly longer cycle time compared to a rotary platen due to the mechanics of the internal rotation. The advanced 2k injection molding process is perfectly demonstrated by this method.

Core Slide and Lifter Mechanisms: A Non-Rotary Solution

Not all 2K parts require rotation. For simpler geometries, a core slide or "core back" mechanism provides a clever and efficient solution. This method creates the second-shot geometry by moving a portion of the mold's core after the first shot is complete. The part never leaves its original cavity.

How Do Core Slides Work in 2K Molding?

In this process, the first material is injected to form the substrate. After the material has solidified, the mold opens slightly, or a hydraulic/mechanical actuator pulls a specific section of the core back. This retraction creates a new, empty space around or on the substrate. The mold then closes, and the second material is injected into this newly created void.

Think of it like a retractable pen. The first shot forms the main body of the pen. Activating the core slide is like retracting the writing tip, which creates a space inside. The second shot then fills this space. This technique is excellent for creating parts with integrated seals, bands, or layers, such as those used in Soft Touch Grips 2K Molding.

Applications and Limitations

Core slide mechanisms are best suited for parts where the second material does not need to fully encapsulate the first. This method shines when adding a soft TPE layer onto a rigid handle or molding a gasket directly onto a housing. The main advantage is that the mold design is often simpler and less expensive than a rotary mold. Furthermore, these molds can be run in a standard injection molding machine that has core-pull functionality.

The primary limitation is geometric. This method cannot be used for parts that require the second material to be on opposite sides of the substrate. It is purely for adding material adjacent to the first shot. This is a key point of distinction when comparing 2k injection molding vs overmolding, as both can achieve similar looks but through very different means.

How to Choose the Right Method for Your Project

Selecting between a rotary platen, index plate, or core slide depends on a careful analysis of the project's specific needs. The decision should be based on a balance of part design, production volume, available machinery, and budget. For a broader context, it is helpful to understand the fundamentals of all injection moulding.

A Comparative Overview

Each method offers a distinct set of advantages and disadvantages. Choosing the optimal path requires a clear understanding of these trade-offs. The right choice in 2k injection molding materials is equally important for project success.

- Rotary Platen

- Best for: High-volume production of large or symmetrical parts.

- Pros: Offers the fastest possible cycle time and a very stable, repeatable process.

- Cons: Requires a very expensive and specialized 2K machine, offering less geometric flexibility.

- Index Plate

- Best for: Complex or asymmetrical parts in medium to high-volume production.

- Pros: Highly versatile design options and can sometimes be adapted to standard machines.

- Cons: The mold construction is mechanically complex and can be more expensive to build and maintain.

- Core Slide (Core Back)

- Best for: Simpler overmolds like layers, bands, or gaskets in low to medium-volume runs.

- Pros: The mold is simpler and less expensive, and it can run in a standard machine with core pulls.

- Cons: It has significant geometric limitations and cannot be used for encapsulation.

Frequently Asked Questions

Yes. Both rotary platen and index plate systems can be adapted for 3-shot or 4-shot molding by adding extra stations (120° or 90° rotations). This enables complex multi-material, multi-color parts in one process.

The main issues are wear on rotating mechanisms (bearings, drives), seal leaks in rotary unions, and maintaining precise alignment and locking to avoid mold damage.

Ejection happens at the final station using standard ejector pins. The system is designed so ejection does not interfere with injection or rotation, keeping the cycle efficient.

Yes. Rotary platen is fastest (parallel injection), index plate is slower (internal rotation), and core slide is slowest (sequential shots).

Extremely high. Alignment tolerance is 0.01–0.02 mm, with precise locking and smooth, repeatable rotation. Any error can cause flashing, defects, or mold damage.