How to Maintain and Clean 2K Molds

Maintaining and cleaning a 2K mold requires a rigorous preventative maintenance schedule. This plan should be focused on three key areas: in-press cleaning during production runs, routine bench maintenance between runs, and major periodic overhauls. Special attention must be paid to the complex rotational or slide mechanisms and the critical shut-off surfaces that are unique to these advanced tools.

As builders and operators of high-precision 2K tooling, we know that a mold is a significant capital investment. A disciplined maintenance program is not merely an operational cost; it is the most effective way to protect that investment. Proper care ensures consistent part quality, minimizes unplanned downtime, and maximizes the tool's productive lifespan.

This guide will detail a comprehensive maintenance plan, from daily in-press checks to complete tool disassembly. We will also cover the best practices and modern techniques for effectively cleaning these complex and valuable manufacturing assets.

Why is Maintenance More Critical for 2K Molds?

All injection molds require regular maintenance. However, the complexity of a 2K mold makes a proactive and thorough maintenance program even more critical. These tools have more moving parts and more intricate surfaces than a standard single-shot mold, all of which must work in perfect harmony.

The Challenge of Moving Components

Unlike a standard mold which is largely a static block of steel, a 2K mold contains complex mechanical systems. Whether it uses a rotary platen, an internal index plate, or a series of core slides, these components are in constant motion. This creates wear points that do not exist in simpler tools. The bearings, gears, and locking mechanisms of these systems require regular inspection, cleaning, and lubrication to prevent premature failure and ensure precise alignment.

The Importance of Shut-Off Surfaces

2K molds have two types of shut-off surfaces. The primary shut-off is on the main parting line, just like a standard mold. However, they also have critical internal shut-offs where the mold steel seals against the first-shot plastic part (the substrate). This seal contains the pressure of the second injection shot. Any residue, gas buildup, or wear on these delicate surfaces will allow the second material to seep out, causing flash and rendering the part defective. Keeping these internal shut-offs impeccably clean and sharp is a top maintenance priority.

Two Materials, Two Sets of Residue

The process involves two different polymers, each of which can leave a unique type of residue on the mold surfaces. Some 2k injection molding materials, like PVC or flame-retardant grades, can release corrosive gases during molding. If not cleaned off, these gases can cause rust and pitting on the mold. Other materials, particularly soft TPEs, can leave a sticky residue that can be difficult to remove. The cleaning protocol must be able to handle the specific byproducts of both materials being used.

Creating a Tiered Maintenance Schedule

An effective maintenance plan is not a one-off event; it is a continuous, scheduled process. By breaking down tasks into different levels, a toolroom can ensure that every mold receives the appropriate level of care at the right time. The entire 2k injection molding process relies on the mold being in perfect condition.

Level 1: In-Press Cleaning and Daily Checks (Every Shift)

This is the most frequent level of maintenance, performed by the machine operator while the mold is still in the press. The goal is to address minor issues before they become major problems. This includes wiping down the parting line surfaces with a soft cloth to remove any contaminants. The operator should also clean any visible residue from the mold vents using a soft brass tool. A quick visual inspection for any new scratches, dings, or signs of leaking water lines should be part of the daily routine.

Level 2: Routine Preventative Maintenance (Between Production Runs)

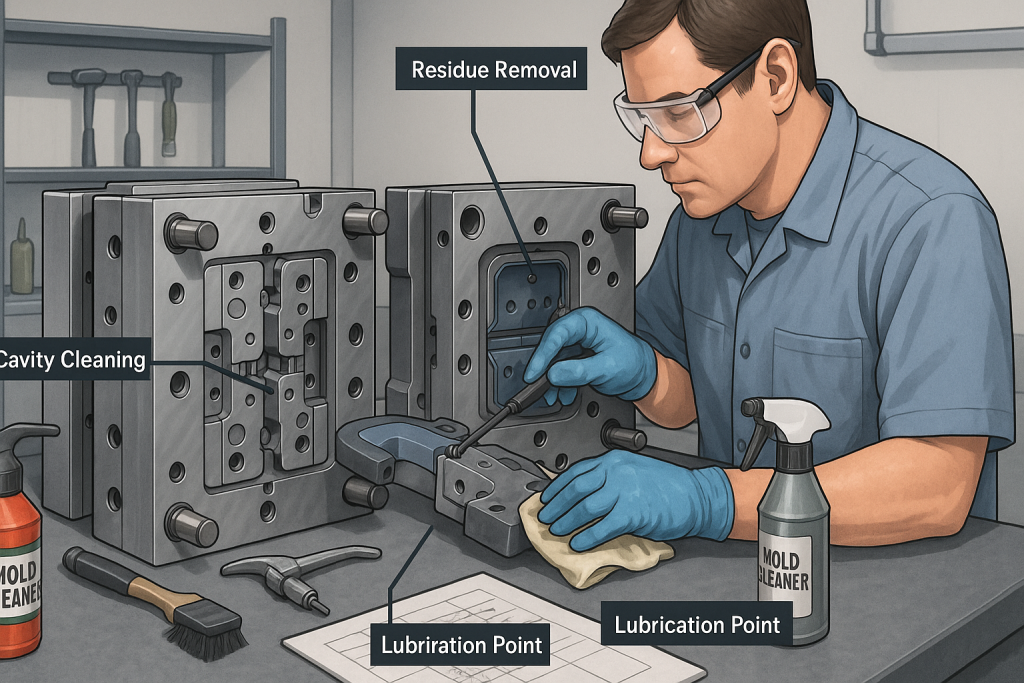

When a specific production run is complete, the mold should be removed from the press for a more thorough service. This is often called a "PM" and is performed by a qualified toolmaker. At this stage, all cavities, cores, and slides are thoroughly cleaned using appropriate solvents. All moving components, including ejector pins, lifters, and slides, are inspected for wear and re-lubricated. The cooling channels are checked for flow to ensure there are no blockages. This is also the time to inspect the critical internal shut-off surfaces for any early signs of wear or damage.

Level 3: Major Overhaul (Annually or After X Cycles)

A major overhaul is a complete, deep-level service that is scheduled based on either time (e.g., annually) or the number of cycles the mold has run (e.g., every 500,000 cycles). For this service, the entire mold is completely disassembled down to its individual components.

Every single part is cleaned and meticulously inspected. Any components that show wear beyond their specified tolerance—such as leader pins, bushings, or ejector pins—are replaced. The parting lines and shut-off surfaces are inspected and may be re-polished or, if necessary, micro-welded and re-machined to restore a sharp sealing edge. This is the ultimate preventative measure to ensure the mold can run for millions of cycles. For a broader context, it is helpful to understand the fundamentals of all injection moulding.

What Are the Best Cleaning Methods for 2K Molds?

Choosing the right cleaning method is crucial. The goal is to remove all contaminants without damaging the highly polished or precisely textured surfaces of the mold. An aggressive cleaning method can be just as harmful as no cleaning at all.

Common Cleaning Techniques

There are several effective methods for cleaning mold components, ranging from simple manual techniques to advanced, high-tech solutions. The best method depends on the type of residue and the component being cleaned. This is especially true for parts like Soft Touch Grips 2K Molding, where texture is a key cosmetic feature.

- Manual Wiping: This is the most common method for in-press and routine cleaning. It is essential to use tools that are softer than the mold steel to prevent scratches. Soft brass or copper scrapers, wooden dowels, and lint-free cloths are standard. Steel tools like screwdrivers or scrapers should never be used.

- Ultrasonic Cleaning: This method is ideal for cleaning small, detailed components like inserts or lifters after the mold has been disassembled. The parts are submerged in a tank with a cleaning solution, and high-frequency sound waves create microscopic bubbles that gently scrub all surfaces clean.

- Dry Ice Blasting: This is a non-abrasive cleaning method that can be used while the mold is still in the press. Pellets of solid carbon dioxide (dry ice) are accelerated in a stream of compressed air and blasted at the mold surface. The combination of the kinetic energy and the thermal shock causes the residue to freeze, crack, and flake off without damaging the steel.

- Laser Cleaning: This is a highly advanced, precise, and non-contact cleaning method. A powerful laser beam is focused on the mold surface. The energy from the laser instantly vaporizes the contaminants, leaving the underlying steel substrate untouched and clean.

Final Thought

Maintaining a 2K mold is not simply about cleaning and repair—it is about preserving precision, reliability, and the return on a major capital investment. These advanced tools contain moving systems, complex shut-off surfaces, and multiple material interfaces that demand a disciplined, structured approach to care. By adhering to a tiered maintenance plan—daily in-press checks, routine preventative services, and periodic deep overhauls—manufacturers can prevent costly downtime, extend mold life, and consistently deliver parts of the highest quality.

A 2K mold that is cared for with rigor is more than just a tool; it becomes a dependable cornerstone of efficient, high-volume production. Preventative maintenance is not an optional overhead—it is the strategy that safeguards performance, protects profitability, and ensures long-term success.