How to Validate and Qualify a 2K Molded Part

Validating a 2K molded part involves a multi-step process focused on three key areas: dimensional accuracy, material bond strength, and functional performance. This process ensures the final component meets every specification. As a manufacturer of mission-critical 2K components, we have a robust qualification process. This ensures every part not only matches the design specifications but also performs reliably in its real-world application. A part that is not properly validated poses a significant risk to product quality and brand reputation.

This guide details the essential steps for a thorough validation and qualification process. We will cover everything from the initial inspections of the first samples to the advanced performance testing required for demanding applications. Following a structured protocol is the only way to guarantee that the part, the mold, and the manufacturing process are all working together to produce a consistent and reliable product.

The Foundation: Dimensional and Visual Inspection

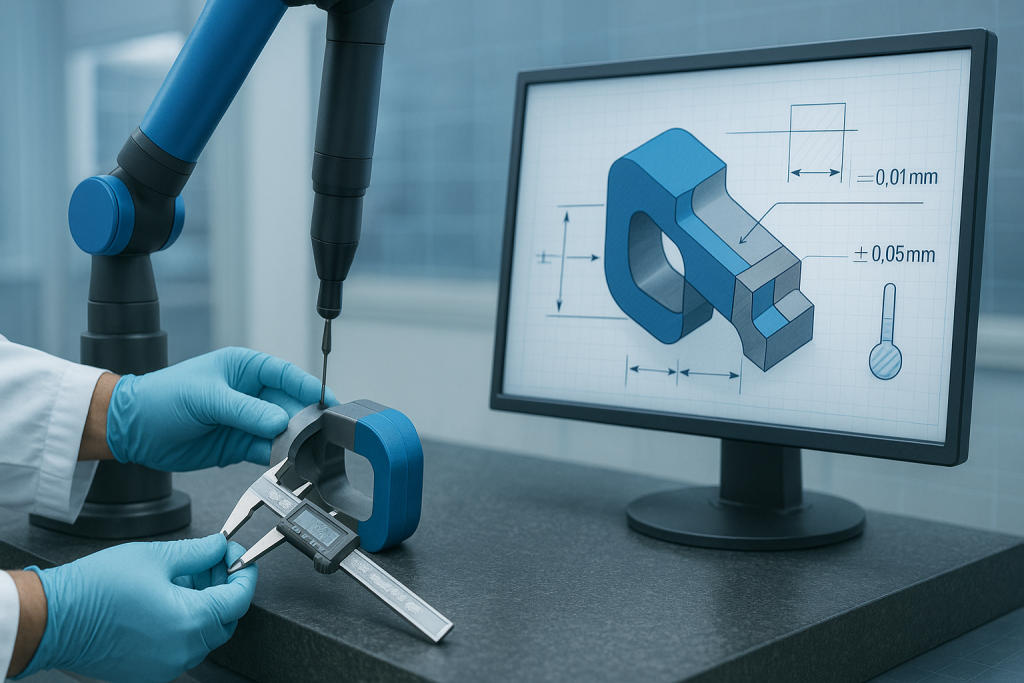

The very first step in validating any new molded part is to confirm that it has been manufactured to the correct size and shape. This is a fundamental check to ensure the mold has been built accurately and the process is stable. This stage combines precise measurement with expert visual assessment.

What is a First Article Inspection (FAI)?

A First Article Inspection, or FAI, is a formal process where the very first parts produced from a new tool are meticulously measured. The goal is to verify that every single dimension on the engineering drawing has been met. This is a comprehensive review that creates a baseline for all future production.

This process uses a variety of metrology tools. Simple dimensions might be checked with digital calipers and micrometers. For more complex geometries and tighter tolerances, a Coordinate Measuring Machine (CMM) is used. A CMM uses a highly sensitive probe to take precise measurements of the part's surfaces. Modern validation may also use non-contact 3D optical scanners to create a complete digital map of the part, which can then be compared directly to the original CAD file. The results are compiled into a detailed FAI report. The general principles of 2K Injection Molding depend on this initial accuracy.

Why is Visual Inspection Critical for 2K Parts?

Alongside precise measurement, a thorough visual inspection is crucial. An experienced quality engineer will examine the first articles for any common molding defects. These include issues like flash (excess material), sink marks (surface depressions), short shots (incomplete parts), and flow lines.

For 2K parts, the visual inspection is even more critical. Special attention is paid to the boundary line where the two materials meet. This shut-off line should be crisp, clean, and consistent. There should be no signs of color bleeding, where pigment from one material migrates into the other. The overall cosmetic finish of both materials must meet the standards set for the final product.

How to Test the Critical Material Bond

The single most important characteristic of a 2K molded part is the strength of the bond between the two materials. If this bond fails, the part fails. Therefore, a significant portion of the validation process is dedicated to testing the integrity of this bond. The entire purpose of the 2k injection molding process is to create this permanent fusion.

Understanding Bond Strength Requirements

The level of testing required depends entirely on the part's application. For a simple cosmetic part where the overmold is for color contrast, a basic qualitative test may be sufficient. However, for a structural component or a medical device, a much more rigorous, quantitative test is necessary to ensure safety and reliability. The validation plan must clearly define the acceptance criteria for the bond strength.

Qualitative Bond Testing Methods

Qualitative tests are fast, simple methods to get a good sense of the bond quality. They do not provide a numerical value but can easily identify a good or bad bond.

One of the most common methods is a manual peel test. A technician uses a cutting tool to create a small tab in the overmolded material and then attempts to peel it back using pliers. In a good part, the bond will be stronger than the material itself. This results in "cohesive failure," where the TPE or TPU material tears, leaving a layer of residue on the substrate. The undesirable outcome is "adhesive failure," where the overmold peels off cleanly, indicating a poor bond.

Another method is the cross-hatch adhesion test. A grid of squares is carefully cut into the surface of the overmold. A special, high-strength adhesive tape is then applied firmly over the grid and pulled off rapidly. If any of the squares of material are pulled off with the tape, the bond is considered a failure.

Quantitative Bond Testing Methods

For critical applications, a numerical value for bond strength is required. The most common method for this is a tensile pull test using a piece of equipment called a tensometer. A sample of the 2K part is specially prepared and clamped into the machine. The machine then pulls the two materials apart at a controlled speed and measures the exact amount of force (in Newtons or pounds-force) required to cause the bond to fail. This data can be recorded and compared against a minimum strength specification to provide a clear pass/fail result.

Validating Functional and Environmental Performance

A part can be dimensionally perfect and have a strong bond, but it is not fully validated until it proves it can perform its job in its intended environment. This stage of testing moves beyond the lab and simulates the real-world conditions the part will face during its service life.

Does the Part Function as Intended?

The first step is functional testing. This often involves a fit check, where the 2K part is assembled into its final product. Does it mate correctly with other components? Are the clearances correct? For parts like ergonomic Soft Touch Grips 2K Molding, this stage also involves user testing. Does the part feel right? Is the grip effective? Is the texture appropriate? Any issues found here can point to subtle dimensional or material problems that were not caught in the initial inspections.

How Will the Part Survive in its Environment?

Environmental testing subjects the part to the stresses it will encounter over its lifetime. The specific tests depend on the product's use case.

- Thermal Cycling: Many products are exposed to fluctuating temperatures. Parts are placed in a thermal chamber and subjected to cycles of extreme heat and cold. This is especially important for 2K parts, as the two materials will expand and contract at different rates. This test checks if this differential stress weakens the bond over time.

- Chemical Resistance: The part is exposed to any chemicals it might encounter during use, such as cleaning agents, oils, fuels, or solvents. After exposure, the part is inspected for any signs of material degradation, swelling, or loss of bond strength. This is critical for choosing the right 2k injection molding materials.

- UV Exposure: For parts used outdoors, accelerated UV testing is essential. The parts are placed in a chamber that bombards them with intense UV radiation to simulate years of sun exposure in a matter of weeks. This checks for color fading, embrittlement, or bond failure due to UV degradation.

The Full Qualification Process: IQ, OQ, PQ

In regulated industries such as medical and automotive, a more formal and documented process called qualification is required. This process uses a framework of Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to prove that the manufacturing process is stable and repeatable. This level of rigor is a key differentiator when comparing 2k injection molding vs overmolding.

Key Steps in a Process Qualification Run

The final stage, Performance Qualification (PQ), is a simulated production run designed to prove that the process can consistently produce good parts over an extended period. A typical PQ protocol involves several key steps. For a broader context, it is helpful to understand the fundamentals of all injection moulding.

- Define the run length, typically consisting of three separate, successful runs of a few hours each.

- Use a single, consistent batch of raw material for all runs to minimize variation.

- Prohibit any adjustments to the molding process parameters once a run has started.

- Collect and inspect parts from the beginning, middle, and end of each of the three runs.

- Perform full dimensional measurements on a statistical sample of these parts.

- Use statistical process control (SPC) tools to calculate process capability indices (like Cpk and Ppk) to prove the process is statistically stable and capable of meeting the required tolerances.

Frequently Asked Questions

Validation is the high-level process of confirming that the final part meets the overall needs of the user and its intended application. It answers the question, "Did we make the right part?"

Qualification is the specific, documented process of proving that the manufacturing equipment and process are capable of producing that part repeatedly and reliably.

Creating a validation plan is a collaborative effort. The customer (the product owner) is responsible for defining the ultimate requirements and acceptance criteria. They know how the part needs to function and what constitutes a success or failure.

The number of parts required for an FAI depends on the mold's design and the part's criticality. A common practice for a multi-cavity mold is to perform a full, 100% dimensional layout on 3 to 5 parts taken from each cavity.

In a bond test, "cohesive failure" is the ideal outcome. It means that the adhesive bond between the two materials is stronger than the internal, or cohesive, strength of the weaker of the two materials. When you try to pull them apart, the material itself tears, leaving a layer of residue on the substrate.

It depends on the nature of the change and the criticality of the product. A full IQ/OQ/PQ is usually not necessary, but some level of re-validation is always recommended.