What is Dual Material Tooling and How Does It Work?

Dual material tooling, also known as 2K or two-shot injection mold tooling, is a sophisticated type of mold that allows two different plastic materials to be injected and chemically bonded into a single, finished part during one machine cycle. It works by using complex internal mechanisms, like a rotating platen or retractable cores, to reposition the first injected part (the substrate) to receive the second injection. This advanced technology is the key to efficiently manufacturing integrated, multi-material components at scale.

Key Takeaways

- What it is: A single, complex mold with two different cavities designed to form a two-material part in one press.

- How it works: It typically injects one material, rotates the mold's core half 180 degrees, and then injects the second material over the first.

- Main Types: The most common mechanism is a rotational platen, but other methods like sliding cores are also used.

- Why it's used: To achieve a superior, permanent bond between materials and gain massive production efficiency for high-volume runs.

What is Dual Material Tooling? (And How It Differs from Standard Molds)

Dual material tooling is a single mold base that contains two different sets of cavities and cores, allowing it to produce a complex, two-material part in one press cycle. Unlike a standard injection mold, which has one cavity to produce one part from one material, a 2K tool is essentially two highly integrated and precisely aligned molds within a single tool.

To understand the difference, an analogy can be helpful. Think of it like a book:

- A standard mold is like a single page. The press closes, injects plastic, and ejects a finished part. The process is complete.

- Dual material tooling is like two facing pages in that book. After the first page is "printed" (injected with Material A), the book's spine (the mold's rotating center) turns the page, presenting that first part to the second page. The press then closes and "prints" Material B onto the first part, completing the component.

This specialized tooling is the engine that drives the entire process we explain in How 2K Injection Molding Works. It’s this intricate design that enables the seamless integration of two materials without manual handling or secondary operations.

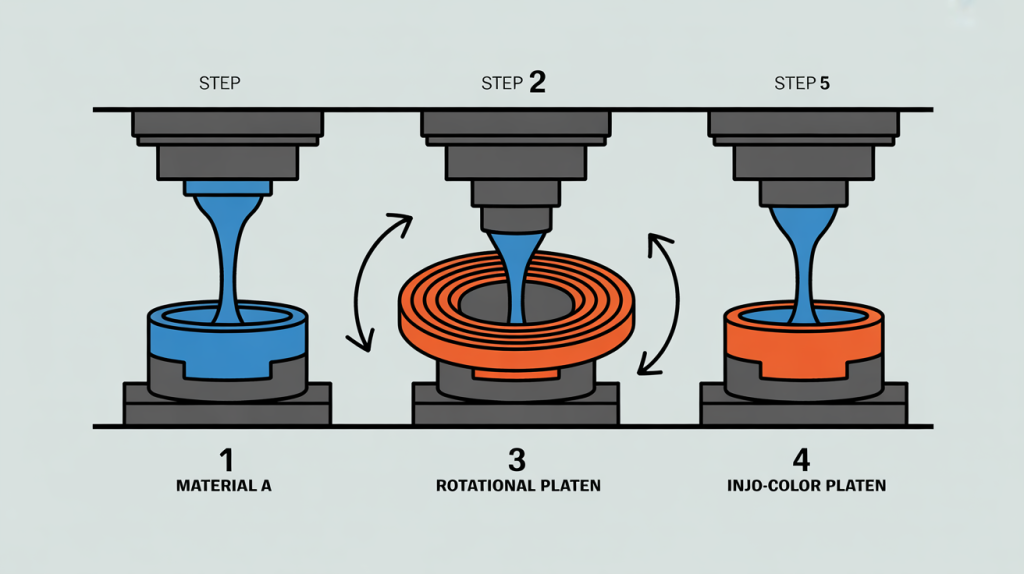

How Dual Material Tooling Works: A 4-Step Cycle

The most common type of dual material tooling uses a rotational platen. The process is a marvel of efficiency, producing a finished, two-material part with every cycle. Here’s a step-by-step breakdown of how it works.

Step 1: First Shot Injection

The cycle begins as the two halves of the mold close. The first injection unit on the press injects Material A (e.g., a rigid polypropylene) at a specific temperature and pressure into the first cavity. This shot forms the substrate, or the main body, of the part.

Step 2: Mold Repositioning (The 180° Rotation)

Once the first shot has partially cooled but is still hot enough to form a chemical bond, the mold opens slightly. The central platen of the mold, which holds the core side, then rotates a precise 180 degrees. This action moves the newly molded substrate from its initial position over to the second, larger cavity.

Step 3: Second Shot Injection

The mold closes again, now with the substrate perfectly positioned in the second cavity. The second injection unit on the press injects Material B (e.g., a soft, flexible TPE) into the second cavity. This new material flows into, onto, or around the waiting substrate, fusing with it on a molecular level to create a permanent bond.

A key to the process's efficiency is that while this second shot is happening, the first injection unit is already injecting the next substrate in the first cavity. This means both injection units are working in parallel.

Step 4: Cooling and Ejection

Finally, the entire part cools to a solid state. The mold opens for the last time, and an ejector system, often with a robotic arm, removes the single, finished, two-material component. With the finished part ejected, the mold is already rotating the next substrate into position, and the cycle repeats seamlessly, often in under 60 seconds.

The Main Types of Dual Material Tooling Mechanisms

The primary mechanisms for dual material tooling are rotational platen and core-back tooling. The choice between them depends entirely on the part's geometry and the relationship between the two materials.

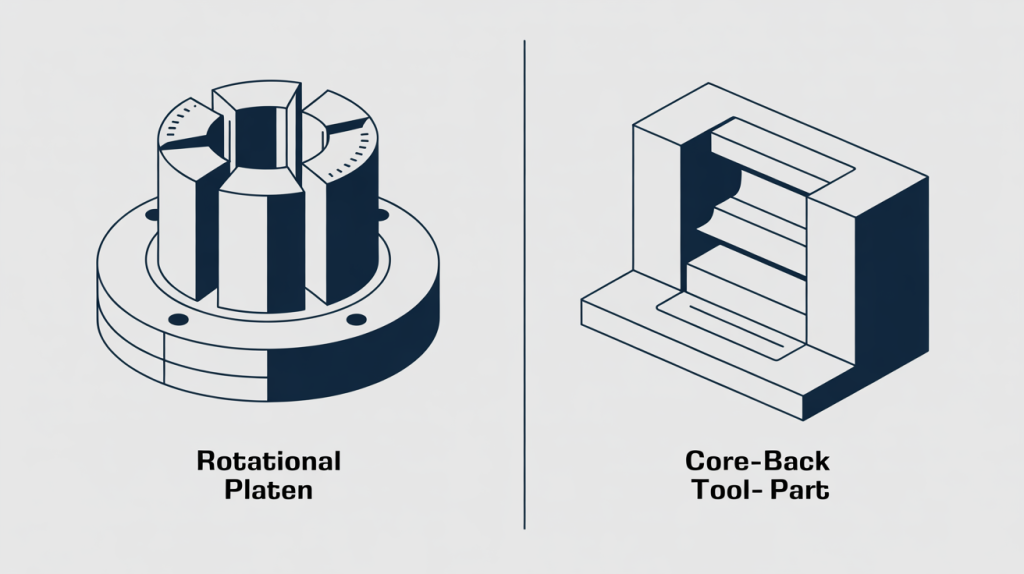

Rotational Platen Tooling

This is the 180-degree rotation method described in the cycle breakdown and is the most common and versatile type of 2K tooling. After the first shot, the core half of the mold rotates to move the substrate into the second cavity.

- Best Suited For: Complex parts where the two materials are side-by-side, wrap around each other, or require 360-degree integration. It’s the go-to method for creating parts like power tool handles with full soft-touch grips, watertight enclosures with integrated seals, or automotive buttons with molded-in icons.

Core-Back (or Sliding Core) Tooling

In this clever design, the mold does not rotate. Instead, after the first shot of material is injected, a section of the mold steel, called a slide or core, retracts or moves away. This action creates a new, empty space within the same cavity. The second material is then injected into this newly created void.

- Best Suited For: Parts that involve layering one material over another in a simpler geometry. It’s perfect for adding a soft-touch surface on top of a rigid base, creating a flexible living hinge between two rigid sections, or molding a window into a housing.

Comparison Table: Rotational Platen vs. Core-Back

| Feature | Rotational Platen Tooling | Core-Back (Sliding Core) Tooling |

| Complexity | Very high; essentially two molds in one. | High, but generally simpler than rotational. |

| Mold Action | Core half of the mold rotates 180°. | A slide or core retracts within the mold. |

| Part Geometry | Ideal for complex, multi-sided parts. | Best for simpler, layered geometries. |

| Common Use Cases | Full grips, integrated 360° seals, complex buttons. | Soft-touch pads, flexible hinges, windows. |

| Press Requirements | Requires a press with a rotational platen. | Can sometimes be used in a standard press with core-pull circuits. |

Export to Sheets

Critical Design Considerations for Dual Material Tools

A successful dual material tool is a major engineering achievement that requires deep expertise in material science, mold flow, and precision machining. It is not simply a matter of adding a second cavity; the entire tool must be designed to manage the complex interaction between two different materials under immense heat and pressure.

Material Compatibility and Bonding

The tool must be designed around the specific thermal and flow properties of both plastics. A strong chemical bond only occurs when the two materials are compatible and the second shot is injected while the first is at the optimal temperature. The tool's cooling channels must be engineered to maintain this temperature perfectly. This choice is governed by the principles in our 2K Injection Molding Materials Guide.

Shut-Off Surfaces

Shut-off surfaces are the precise areas where the two halves of the mold (or slides and cores) meet to contain the high-pressure molten plastic. In a 2K tool, creating a crisp, clean boundary between Material A and Material B requires incredibly precise shut-offs. Any microscopic gap can cause "flash," where the second material bleeds onto the first, ruining the part. These surfaces must be machined to extremely tight tolerances and designed to withstand millions of cycles without wear.

Gating and Cooling

The tool must have two completely separate gate and runner systems to deliver each material to its respective cavity. The gate locations are critical to ensure the plastic fills the cavity properly without creating defects. Furthermore, the tool needs a complex network of cooling channels to manage the different temperatures required by each material and to ensure the part cools evenly, preventing warpage.

Differential Shrinkage

Nearly all plastics shrink as they cool. When you use two different materials, they will almost certainly shrink at different rates. The tool designer must calculate these different shrinkage rates and machine the cavities to compensate for them. For example, the cavity for a material that shrinks more will be made slightly larger. Failure to manage differential shrinkage will result in a warped, dimensionally inaccurate part. This complexity is a key factor when comparing 2K Injection Molding vs. Overmolding.

Mini-FAQ

Dual material tooling is a significant investment, often costing 30-50% more than a comparable single-shot mold, and sometimes even more depending on the complexity. This is due to the larger mold base, the intricate internal mechanisms like the rotational platen, and the extensive design and machining time required. However, this upfront cost is typically justified for high-volume production, as it eliminates the cost of manual assembly, leading to a lower overall cost per part.

This tooling requires a specialized injection molding press. The machine must have two independent injection units (or barrels) to melt and inject the two different materials. If using a rotational tool, the press must also be equipped with a rotational platen and the control system necessary to manage the complex, multi-step cycle.

The design and fabrication of a dual material tool are incredibly complex. An expert partner is crucial because they have the deep engineering knowledge to manage the interaction of two materials, design precise shut-off surfaces, calculate differential shrinkage, and optimize cooling. Mistakes in the design phase are extremely costly and can lead to a tool that simply does not work, making partnership with an experienced mold maker essential.

Conclusion

Dual material tooling is the sophisticated and powerful technology that makes high-volume, high-quality 2K injection molding possible. While it represents a significant investment in engineering and capital, its ability to create fully integrated, multi-material parts in a single, automated cycle is unmatched in efficiency and part quality. Understanding the mechanics of how this tooling works is the first step for any designer or engineer looking to leverage the full potential of multi-material components.

To see the end results of this incredible technology, explore these common 2K injection molding applications.