Plastic Injection Molding

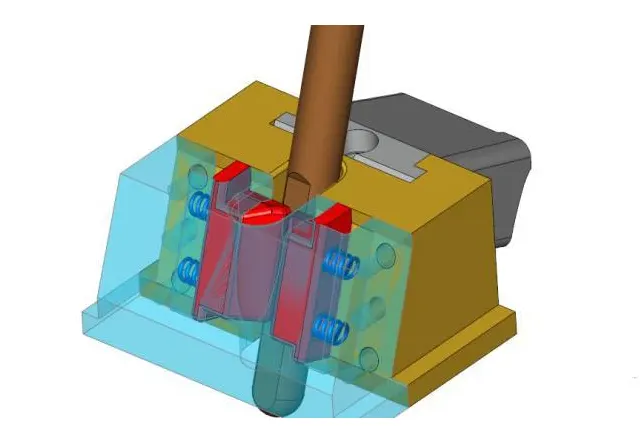

Plastic injection molding provides high-volume production of consistent, durable parts with excellent repeatability. The process enables complex geometries and thin-walled designs while maintaining tight tolerances (±0.1mm). With fast cycle times and low per-unit costs, it's ideal for mass production across industries like automotive, consumer goods, and medical devices.

- Thermoplastics (ABS, PC, Nylon, etc.)

- High-Cavity/ Multi-Cavity Molds for Mass Production

- Overmolding / Insert Molding for Multi-Material Parts

- 7-30 Day Lead Time with Production Quantities (1k-1M+ pcs)

- Surface Finishes: Glossy/Matte/Texture/UV Coating/plating/etc.

- Custom Mold Design & Rapid Tooling Options

- Overview

- Production Capability

- Materials

- Finishes

- Why Choose Us

- Resources

Expertise in High-Performance Molding

At SunOn, we provide reliable custom plastic injection molding service solutions tailored to meet diverse industry needs. Using advanced machinery and precision tooling, we deliver high-quality plastic components that ensure durability, consistency, and efficiency. Our services are ideal for businesses seeking mass production with strict quality requirements.

Our plastic injection molding service supports projects from prototype development to large-scale manufacturing. With a focus on customization, we create molds that meet unique design specifications and functional requirements. Every part undergoes rigorous testing to ensure performance and compliance with international standards.

Applications of Custom Plastic Injection Molding Service

Our custom injection molding service is widely used in:

-

Automotive Industry – dashboards, panels, and connectors

-

Medical Devices – precision components for instruments and casings

-

Consumer Products – housings, packaging, and everyday items

-

Electronics – connectors, enclosures, and protective casings

-

Industrial Equipment – durable plastic parts for heavy-duty use

These applications highlight the versatility of our injection molding expertise.

Benefits

Choosing SunOn for plastic injection molding service provides distinct advantages:

-

Design Flexibility – molds tailored to complex shapes and unique specifications

-

Material Versatility – wide range of plastics suited for different applications

-

High Production Speed – efficient process for mass production at scale

-

Quality Assurance – parts inspected for accuracy, strength, and durability

-

Cost Efficiency – reduced waste and optimized manufacturing processes

With our expertise, we help businesses bring innovative designs to life with precision and efficiency.

From Raw material to Finish parts

We offer comprehensive plastic injection molding services—from initial design optimization and mold engineering to prototyping and high-volume production. With advanced machinery and technical expertise, we transforming raw polymer resins into high-quality finished components. Our process ensures precision, efficiency, and consistency—from material selection to final inspection and packaging.

Material Preparation

Resin drying (for hygroscopic materials) Color mixing/masterbatching Additive incorporation (fillers, reinforcements)

Mold Setup

Mold installation and clamping Temperature setting (mold & barrel) Process parameter configuration

Injection Phase

Resin melting in the barrel (180-300°C) Injection under high pressure (700-1500 bar) Packing pressure application

Cooling Phase

Controlled cooling time Part solidification Mold temperature maintenance

Ejection

Mold opening Ejector pin activation Automated part removal

Get Precision CNC Parts Today

We offer precision CNC machining with fast turnaround, supporting various materials and part complexities. Ideal for prototyping or scaling up production, with consistent quality every step of the way.

Materials for Manufacturing

We offer a range of materials, including plastics, metals, and composites, selected for their strength, durability, and resistance to heat and chemicals. These materials ensure high-quality, long-lasting products for industries like automotive, electronics, and medical.

We can source any other materials upon request! If you don't see the material you need please contact us

Some of Our Samples

These samples highlight our expertise, but we provide a wide range of additional services.

Why Choose Us?

SunOn Industrial Group Limited offers end-to-end services from product design to mass production, specializing in high-quality solutions for industries like home appliances, automotive, and medical devices. With over 25 years of experience and a global presence, we ensure reliable, cost-effective solutions and seamless service from prototype to final assembly.

- One-stop solutions from prototype to packaging.

- Timely support across 27 cities worldwide.

- Experienced engineers ensuring quality results.

- ISO 9001, IATF 16949, ISO 14001 certified.

Industry Application

We produce millions of parts for diverse industries, including automotive, medical, robotics, automation, communications, consumer electronics, and LED lighting, delivering top-quality products.

FAQs

When can I get the price?

Could you provide a sample for us?

What is your MOQ for the products?

Do you have any parts in stock?

When did you start to export moulds to USA and Europe?

What is your main product?

Manufacturing Resources

Start production of your parts today