Two-Shot Molding Service | Custom 2K Injection Molding 2025

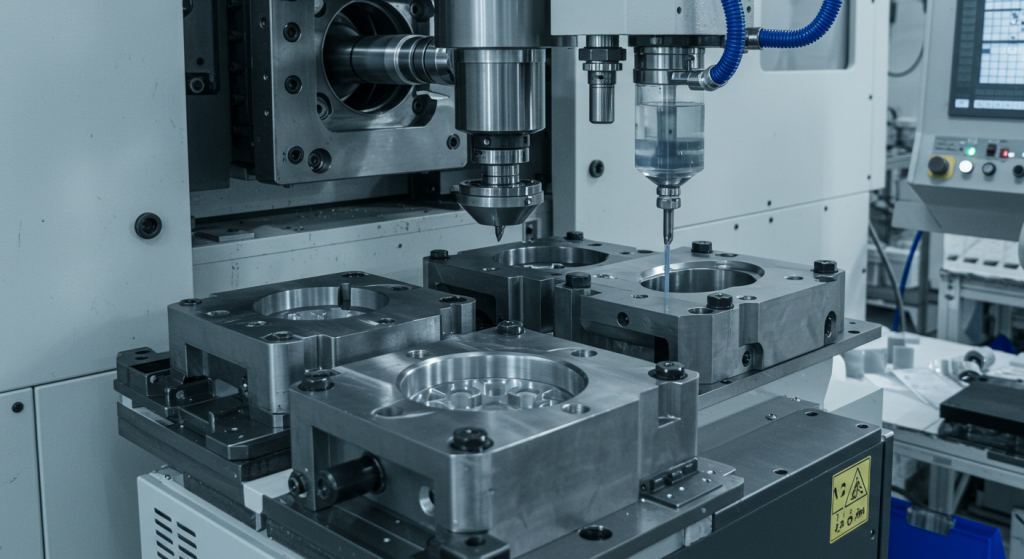

What is Two-Shot Molding Service?

Two-shot molding Two-shot molding Two-shot molding is a specialized service, a multi-shot injection molding service that uses two different thermoplastics/colors injected sequentially into the same mold in a single cycle. Compared to conventional methods (molding), in two-shot molding, multiple materials are incorporated directly into the mold, producing one non-piece product. It usually entails:

- First Shot- This is an injection of the base material or substrate, which is usually a rigid plastic such as ABS or polycarbonate.

- Mold Rotation or Transfer- The substrate rotates or moves in the two-shot mold design, and this will position it for the second material.

- Second Shot- Injection of the third material that might be of another color or a softer polymer, such as TPE (thermoplastic elastomer).

- Cooling and Ejection- Cools and ejects the final part; no further assembly is needed.

This forms dual-color plastic molding services or soft-touch molded grips, or even sealed plastic enclosures in one manufacturing action.

Two-Shot Molding Service: Technology, Uses, and Benefits

- In the rapidly changing world of plastics production, innovation is the key to success. In the modern business world, products are required to be not only durable and precise but also stylish, functional, and affordable. The two-shot molding service, also known as dual-shot molding service, two-shot molding service, or 2K injection molding service, is one technology that towers on this crossroads of performance and creativity.

- Since the time of its development, this process has turned out to be a landmark in the manufacturing industry, where it has allowed firms to make multi-material plastic components with unmatched efficiency and beauty. It is in automotive two-shot molding, medical device two-shot molding, or consumer electronics two-shot molding that this process opens opportunities that cannot be easily matched by single-material processes.

Technology Two-Shot Molding

The art of two-shot injection molding is as beautiful as it is so engineeringly complex and precise. These are the main technical characteristics:

- Dual-Material Injection Process: In this process, two compatible plastics are injected one after the other in order to make a bond.

- Hot Runner Two-Shot Molding System: Provides consistency in the flow of materials, which reduces the problem of defects.

- Complex Mold Engineering: Design: It needs a well-trained designer to control several cavities and movements.

- Thermoplastic Elastomer (TPE) Over Molding: Flexible grips, seals, or cushioning are often done using thermoplastic elastomer.

- High-Precision Molding Solutions: Able to manufacture complex geometries to close tolerances.

- Modern Injection Molding Technology: Adds robotics and automation to be fast and consistent.

Two-Shot Molding Service Uses

This technology applies to almost all industries due to its flexibility. But where does it shine the best?--let's see:

Automotive Two-Shot Molding

- Two-shot plastic components are used in the automotive industry, like dashboard knobs, switches, handles, and lighting covers.

- Multi-material components are durable under stress and vibration, and high temperatures.

- Improved aesthetics that are dual-color plastic molding service in branding or functionality.

Two-Shot Molding of Medical Devices

- Medical molding services are used to develop housing for surgical equipment, drug delivery systems, and diagnostic equipment.

- Molded grips that are soft touch enhance the ergonomics and safety of the user.

- Materials that are contaminated by sensitive medical electronics are safeguarded by sealed plastic structures.

Consumer Electronics Two-Shot Molding

- Remote controls, game controllers, and smartphones: consumer electronics plastic components.

- Multi-color button and keypad molding programs provide durability coupled with increased design.

- Precision plastic housings are soft-touch

Benefits of Two-Shot Molding Service

There are various advantages of the introduction of the two-shot molding service:

- Design Flexibility: This allows multi-layer plastic component production with embedded features.

- Cost Efficiency: Removes assembly processes, lessens labor, and lessens handling of parts.

- Stronger Bonding: This is where two materials are bonded without using adhesives or screws.

- Aesthetic Appeal: Favors dual-color plastic molding service, branding, and high-quality finishes.

- Performance Enhancement: Develops seals, grips, or complicated geometry plastic molding, which enhances utility.

- Sustainability: Consumers use fewer resources in favor of environmentally friendly manufacturing objectives.

Trends in Two-Shot Molding in the Future

The future of two-shot molding service is bright and determined by further development in technologies as well as market demands:

- Integrated Molding Solutions: Multiple processes, e.g., co-injection molding service with automation.

- State-of-the-Art Polymer Processing: Implementation of bio-based and recyclable plastics in 2-shot.

- Lightweight Resilient Plastics Fabrication: This is of particular concern in electric cars and handheld electronics.

- New Plastic Molding Technologies: Intelligent plastics with sensors in them or functional surfaces.

- Expansion of the Global Market: The industries are demanding outsourced two-shot plastic molding in order to fulfill their production demands.

Why Select SunOn Molds to Get Two-Shot Molding?

At SunOn Mold, we specialize in offering two-shot plastic molding services to various industries. Having experience in multi-component molding service and dual-material injection molding, our team provides accuracy, innovation, and dependability in each undertaking. What sets us apart:

- Developed two-shot mold design services for the complex projects.

- Advanced technology of high-precision two-shot molding.Longstanding automotive, medical, and consumer electronics molding experience.

- Scalable and cost-effective for small and large production runs.

In selecting SunOn, you have a partner who is not only dedicated to meeting expectations in integrated molding solutions but also dedicated to providing them.

Conclusion

Several industries that place importance on precision, beauty, and efficiency are quickly expanding and in need of two-shot molding service. It gives manufacturers unprecedented benefits in the flexibility of design, cost reduction, and product performance by allowing the easy integration of two materials or colors into a single part. To the companies looking to exploit the full potential of this technology, engaging experts such as SunOn Mold is a sure way to make sure the concept is successful upon reaching the production stage. Our advanced equipment, technical skills, and interest in innovative plastic molding technology are bound to make your ideas work.